Process Improvements

Kevin resolved some of the outstanding chemical plant commissioning issues at Croda's coatings and resin facility in Malaysia. These included throughput issues on a batch reactor utilising an external hot oil heating coil.

Whilst at Enichem Elastomers in Southampton Kevin specified improvements to the process which included a major plant extension and a number of product quality improvement measures.

Kevin has also used a continuous improvement methodology in order to bring about a step change in plant performance. Simplifying the plant data retrieval process allows for easy prioritisation in the improvement process. Overall equipment effectiveness (OEE) is a key plant performance measure. Improvements in mean time to repair (MTTR) as well as mean time between failures (MTBF) lead to an improvement in the OEE.

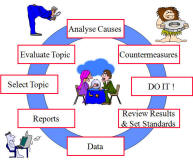

Continuous Improvement Methodology

A continuous improvement methodology has been used in order to identify problems and lost opportunities on large scale chemical plants. The structured approach to problem solving can significantly enhance a plant's overall equipment effectiveness.